Industry news

Home>News > Industry newsHigh chromium white iron cast alloy ASTM A532 15/3CrMo or 25%Cr

HIGH CHROMIUM ALLOY MARTENSITIC WHITE IRON

DESCRIPTION

High chrome white iron cast alloy is a high alloy martensitic white iron with an excellent abrasion and corrosion resistance. Section thicknesses of up to 8 inches can be fully air hardened. The alloy can be annealed, machined and hardened for use in machined abrasion resistant parts. Abrasion resistance is excellent under conditions of high stress abrasion (grinding), low stress abrasion ( scratching), gouging abrasion, slurry erosion and corrosion/erosion. Although it is significantly tougher than low alloy pearlitic white irons, high chrome white iron cast alloy is not suitable for applications with severe impact. High chrome white iron cast alloy’s superior wear resistance is due primarily to a high volume fraction of very hard, well-dispersed primary and secondary carbides in a matrix of martensite. The high chromium content provides good resistance in corrosive environments and good oxidation resistance.

COMPOSITION

C % 2.0 - 3.5

Mn % - 1.5 max.

Si % - 1.0 max.

Cr % 14-18, or 25-28

APPLICATIONS

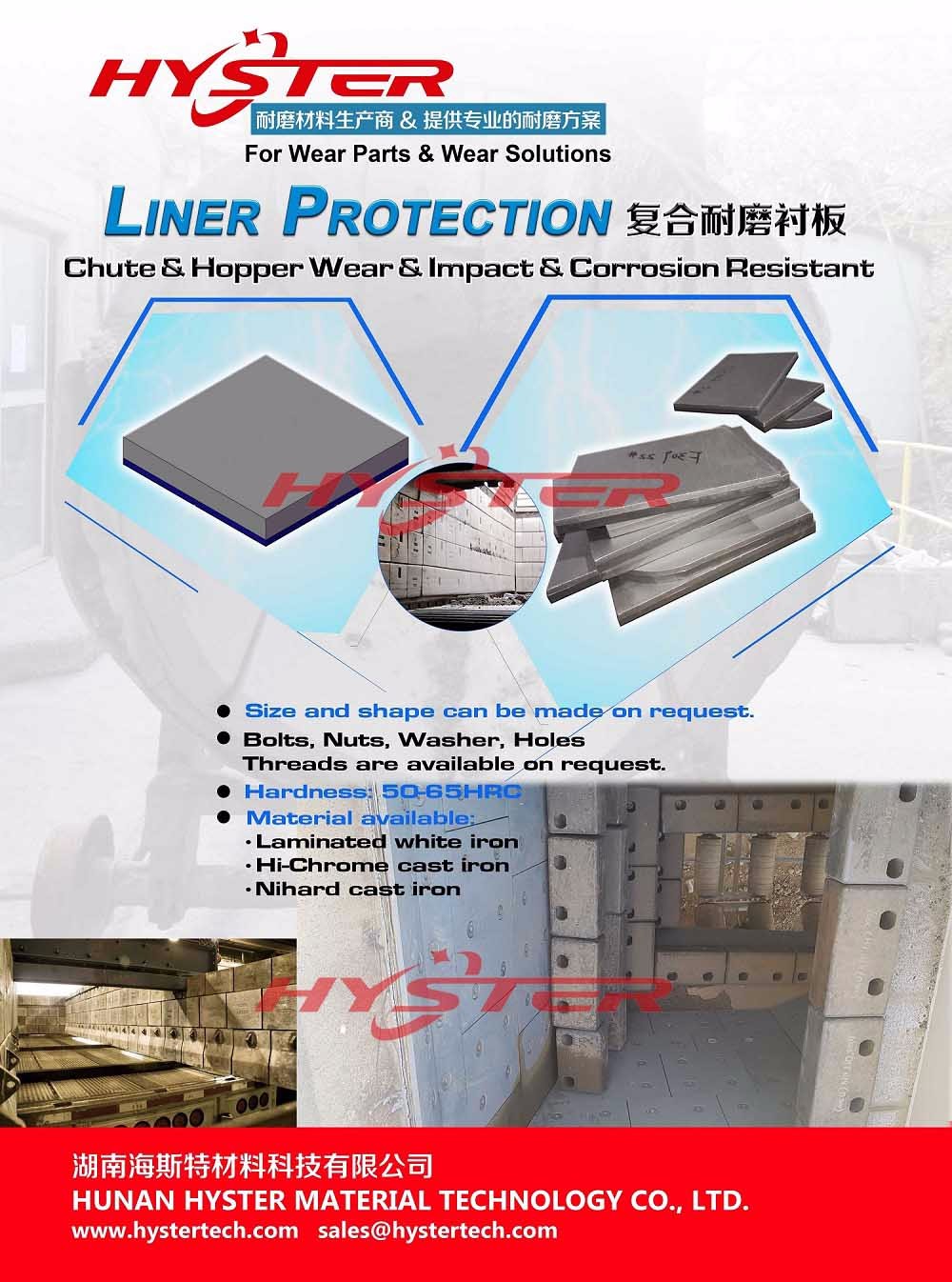

Abrasive and corrosive slurries, briquetting press segments, ball and rod mill liners, sand and dredge pump parts, clay working machine parts, pulverizer impactor and blow bars, tires and grinding rings for roller mill pulverizers, wear plates, chutes and liners, shot blast impeller blades.

TOUGHNESS

Toughness of high chrome white iron cast alloy is better than low alloy pearlitic white iron, however it is not suitable for applications with severe high speed impact, such as hammers. For applications where moderate impact is a concern, alloy 15/3CrMo B with lower carbon content provides improved toughness with only a minimal loss of hardness, although corrosion resistance is reduced.

CORROSION RESISTANCE

The high corrosion resistance of high chrome white iron cast alloy makes it ideal for use in corrosive and abrasive slurries, where the combined effects of corrosion/erosion render low alloy white irons unsuitable. Significant increases in life have been observed in environments of nitric and phosphoric acid slurries.

HARDENABILITY

Section thicknesses of up to 8 inches may be hardened for high chrome white iron cast alloy.

MACHINABILITY

High chrome white iron cast alloy is machinable in the annealed condition, using carbide tools.

SERVICE TEMPERATURE

The alloy is suitable for service at temperatures up to approximately 600℃

WELDABILITY

Welding of high chrome white iron cast alloy is not recommended.

RELATED SPECIFICATIONS

ASTM A532 25%Cr grade III type A

ASTM A532 15/3CrMo grade II type B