Industry news

Home>News > Industry newsCharacteristics and uses of wear strips

Characteristics and uses of wear strips

The wear-resistant strip is extruded from ultra-high polymer plastic material (UPE/HDPE/UHMWPE), which is characterized by scratch resistance, aging resistance, high temperature resistance and friction resistance. Mainly used in conveyor belts, automation equipment, conveyor guardrails, such as: large C guardrail, parallel pad rail, round hat guardrail, flat top guardrail, small C guardrail, flat mat, K-shaped strip, Z-shaped strip, etc. A wide range of specifications, can be customized according to the use of the requirements. Its role is to reduce the coefficient of friction.

Material characteristics

The wear-resistant strip is made of rubber (modified PVC) material, which has the characteristics of scratch resistance, aging resistance, high and low temperature resistance.

Material use

It is mainly used for protecting the ground, walls, machinery, and also for conveyor belts, conveyor belts, etc.

Material properties

Mainly in the following aspects (some parameters are compared with common polyethylene wear strips as an example):

1. Extremely high wear resistance The wear-resistant strip has a molecular weight of more than 2 million and a low wear index, which makes it extremely resistant to sliding friction. The wear resistance is 6.6 times higher than that of ordinary alloy steel and 5.5 times higher than that of stainless steel. It is 6 times of nylon and 5 times of PTFE, which greatly improves the service life.

2, very high impact resistance In the existing engineering plastics, the high-molecular-weight wear-resistant strips have high impact toughness values, and many materials may crack, break, break or surface stress fatigue in severe or repeated explosion impacts. This product is tested according to GB1843 standard for cantilever beam impact test without damage, and can withstand external impact, internal overload and pressure fluctuation.

3, excellent chemical resistance

4, good self-lubricity, because the ultra-high molecular weight polyethylene tube contains waxy substances, and its own lubrication is very good. The coefficient of friction (196 N, 2 hours) is only 0.219 MN/m (GB 3960). Self-sliding performance is superior to oil-lubricated steel or brass. Especially in places with harsh environment, dust and sediment, the dry lubrication performance of this product is more fully displayed. Not only can it move freely, but also protect the related workpiece from wear or strain.

5, unique low temperature resistance Ultra high molecular weight polyethylene wear strips are excellent in low temperature resistance, and their impact resistance and wear resistance are basically unchanged at minus 269 degrees Celsius. It is an engineering plastic that can work at temperatures close to zero.

6. Non-fouling property Ultra-high molecular weight polyethylene pipe has good surface non-adhesion due to its small friction coefficient. 7. High impact strength and good toughness. It does not break even if it is subjected to a strong impact at low temperatures. 8. Non-toxic, odorless, no exudate.

Scope of application

The eight characteristics of the wear strips determine the wide range of applications and can be applied in a wide range of industries. Can replace carbon steel, stainless steel, bronze and other materials used in textile, paper, food machinery, transportation, medical, coal, chemical and other sectors. Such as the textile industry, such as shuttles, shuttle rods, gears, couplings, sweeping rods, buffer blocks, eccentric blocks, rod bushings, swinging effects and other impact-resistant parts. In the paper industry, the cover plate, the wiper plate, the compacting parts, the joints, the sealing shaft of the transmission machinery, the deflector wheel, the scraper, the filter, etc.

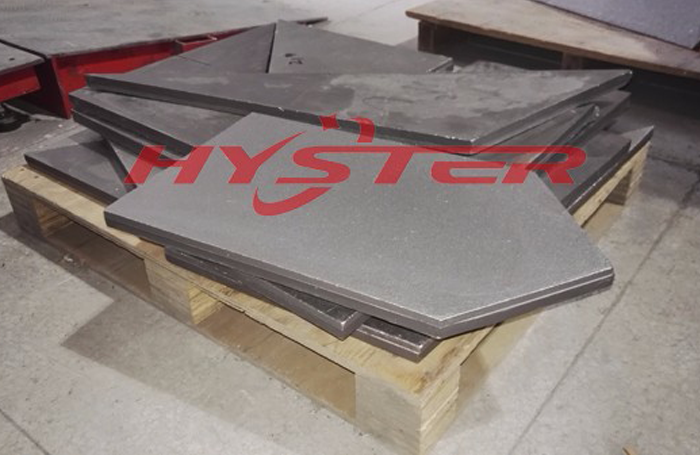

Wear Plates,Wear resistant block,Wear-resisting pipe,Article wear-resisting