Wear bars

Brand : HYSTER / OEM

Product origin : China

Delivery time : Within 7-20 days

Supply capacity : 100 tons per month

Wear bars

We also call them wear blocks, standard wear bars, DLP wear bars.

Material: ASTM A532 15/3CrMo Class II Type B High Chromium White Iron casting(700 BHN-63 Rc) , metallurgically bonded(vacuum brazed) onto mild steel backing plate.

Wear bar products is designed for easy use and installation into chutes, hoppers, bins, impact walls, screen plates and general wear protection in the fixed and mobile plant applications. It can be welded and bolted to suit the needs for the other equipment. Wear bars offer excellent protection when used as tumble bars or when configured to form a rock-box. They are also used to provide protection to heavy earth moving machinery.

Advantages:

Long Life -- Proprietary High Carbon ASTM A532 White Iron with 700 BHN hardness to provide extremely good resistance to severe most of the wear applications. Metallurgically bonded to a weldable steel plate. Impact will not destroy the integrity of the wear resistant face.

Adaptability --Standard carbon steel weld processes are suitable, with no special procedure or preheat requirements. As an alternative to welding, studs can be easily attached or any shape of bolt or screw hole can be incorporated.

Flexibility --Hyster Tech can produce both standard or non-standard sizes and shapes to suit our client's requirements. This includes square, rectangular, round and triangular shapes and sizes to fit a wide variety of wear surfaces. Special shapes can be deigned and supplied as required.

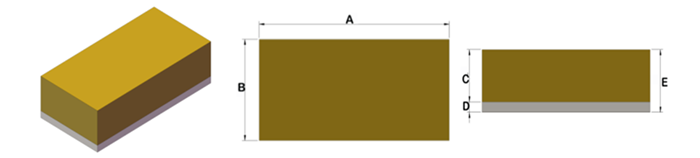

Versatility --The Wear Bar range from 5 mm - 75 mm and the thickness with the steel backing plate ranging from 3 mm - 25 mm. You decide the thickness of the wear resistant layer or choose from our complete line of standard product or have a new design completely customized to fit your needs.

Standard Dimensions and Weight:

Hyster Item No. | Alternative Item No, | Size | Dimension(mm) | N.W. | ||||

(mm) | A | B | C | D | E | (kg) | ||

HSd 200A | DLP 919 | 200x25x25 | 200 | 25 | 15 | 10 | 25 | 1 |

HSd 200B | DLP 1200 | 200x75x75 | 200 | 75 | 63 | 12 | 75 | 8.9 |

HSd 300A | DLP 1191 | 300x25x25 | 300 | 25 | 15 | 10 | 25 | 1.5 |

HSd 153 | DLP 295 | 153x38x33 | 153 | 38 | 25 | 8 | 33 | 1.5 |

HSd 300B | DLP 4 | 300x38x33 | 300 | 38 | 25 | 8 | 33 | 3 |

HSd 190A | DLP 508 | 190x50x30 | 190 | 50 | 20 | 10 | 30 | 2.2 |

HSd 115 | DLP 2265 | 115x50x50 | 115 | 50 | 38 | 12 | 50 | 2.3 |

HSd 127 | DLP 337 | 127x50x50 | 127 | 50 | 38 | 12 | 50 | 2.4 |

HSd 150A | DLP 1101 | 150x50x50 | 150 | 50 | 40 | 10 | 50 | 2.9 |

HSd 190B | DLP 343 | 190x50x50 | 190 | 50 | 40 | 10 | 50 | 3.7 |

HSd 210 | DLP 369 | 210x50x50 | 210 | 50 | 38 | 12 | 50 | 4.1 |

HSd 230 | DLP 125 | 230x50x50 | 230 | 50 | 38 | 12 | 50 | 4.5 |

HSd 294 | DLP 453 | 294x50x50 | 294 | 50 | 40 | 10 | 50 | 5.8 |

HSd 300C | DLP 2017 | 300x50x50 | 300 | 50 | 40 | 10 | 50 | 5.9 |

HSd 300D | DLP 2358 | 300x150x60 | 300 | 150 | 48 | 12 | 60 | 21.1 |

HSd 432 | DLP 201A | 432x50x50 | 432 | 50 | 38 | 12 | 50 | 8.5 |

HSd 450 | DLP 202 | 450x38x31 | 450 | 38 | 25 | 6 | 31 | 4.2 |

HSd 600 | DLP 2230 | 600x50x50 | 600 | 50 | 38 | 12 | 50 | 11.8 |

HSd 150B | DLP 184 | 150x75x39 | 150 | 75 | 29 | 10 | 39 | 3.4 |

HSd 150C | DLP 528 | 150x75x50 | 150 | 75 | 40 | 10 | 50 | 4.4 |

HSd 150D | DLP 619 | 150x75x60 | 150 | 75 | 50 | 10 | 60 | 5.3 |

Note: Studs Extra

If arc studs are required, please stipulate the size and position required.