Skid block

Brand : Hyster, Domite

Product origin : China

Delivery time : 5 days

Supply capacity : 100 tons per month

Skid Blocks

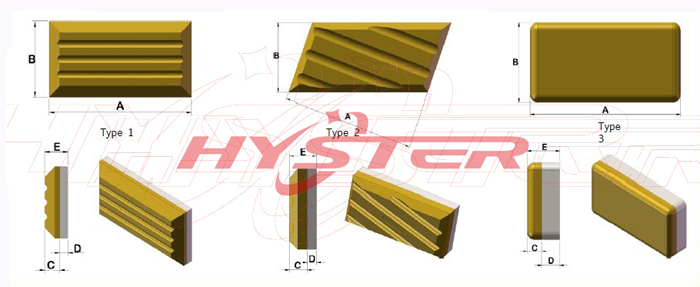

Bottom and Runner Protection for Shovels and Buckets. The Skid Blocks is available in various lengths, widths and sizes, wherein the surface of the bar is smoothly shaped.

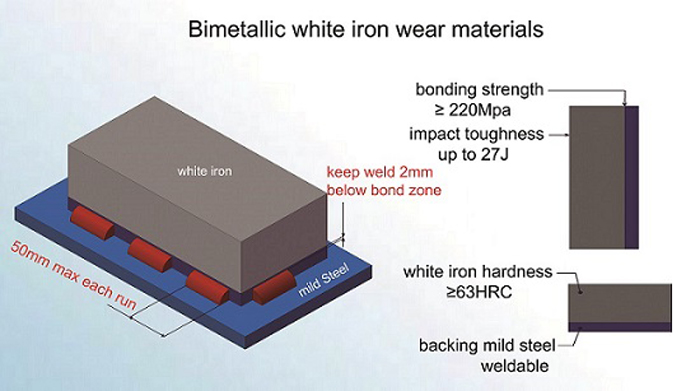

Material: the wear material is ASTM A532 15/3CrMo white iron(hi-chrome carbide casting iron), vacuum brazed with mild steel backing plate. The hardness is above 63HRC/700BHN.

Bimetallic wear blocks, hardness 63HRC min. Typical Data Numbers We received from our End-User:

>White iron wear blocks life is 50% greater than that of Ni Hard Irons.

>At least 7 times longer than A.R. type steels 360/400 BHN

>3 times the wear rate of 500 BHN A.R. Plate

>5 times the wear rate of Manganese Steel

>3 times the wear rate of Weld Hardfacing

>16 times the wear rate of Carbon Steel

ALWAYS THE BEST CHOICE FOR TOUGH APPLICATION!!

Skid block's Photo and detail:

| Type | Item No. | Size | Dimension(mm) | N.W. | ||||

| (mm) | A | B | C | D | E | (kg) | ||

| 1 | SB1-214 | 214x101x34 | 214 | 101 | 22 | 12 | 34 | 5.1 |

| SB1-302 | 302x101x34 | 302 | 101 | 22 | 12 | 34 | 7.3 | |

| SB1-154 | 154x101x34 | 154 | 101 | 22 | 12 | 34 | 3.7 | |

| SB1-279 | 279x75x34 | 297 | 75 | 22 | 12 | 34 | 6.1 | |

| 2 | SB2-214 | 214x101x34 | 214 | 101 | 22 | 12 | 34 | 5.9 |

| SB2-214R | 214x101x34 | 214 | 101 | 22 | 12 | 34 | 5.9 | |

| SB2-302 | 302x101x34 | 302 | 101 | 22 | 12 | 34 | 8.4 | |

| SB2-302R | 302x75x34 | 302 | 75 | 22 | 12 | 34 | 8.4 | |

| SB2-154 | 154x101x34 | 154 | 101 | 22 | 12 | 34 | 4.2 | |

| SB2-154R | 154x75x34 | 154 | 75 | 22 | 12 | 34 | 4.2 | |

| 3 | SB3-250A | 250x150x45 | 250 | 150 | 20 | 25 | 45 | 13.1 |

| SB3-200 | 200x150x45 | 200 | 150 | 20 | 25 | 45 | 10.5 | |

| SB3-250B | 250x250x45 | 250 | 250 | 20 | 25 | 45 | 21.9 | |

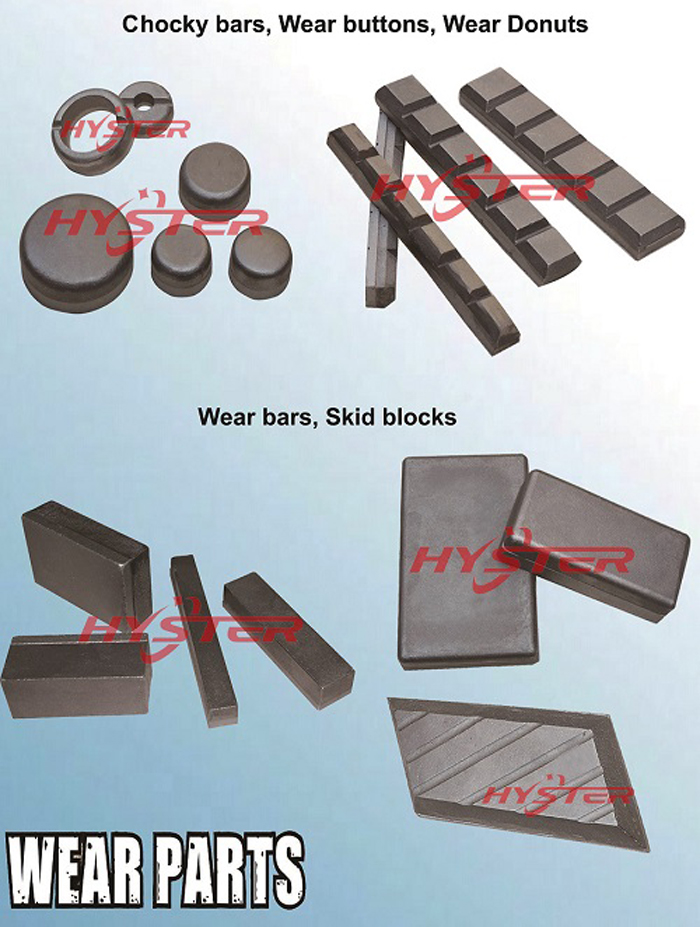

Other Typical Type: Chocky bars, Wear buttons,DLP wear bars, Wear Plates/Liners, Rockboxliners, Micro-ledges, Wafer strips, Skid blocks, Shredder Hammer tips, Knifeedges, Shaped wear bars etc..

Advantages:

1. Good properties of wear resistance, toughness, plasticity, heat resistance, hot hardness.

2. Easy for welding and assembly.

3. Different shapes and sizes available

4. Smooth and flat surface

5. High cost-effective.

6. 3 times more higher usage life compared with overlay plates

Application:

1. Widely used in the abrasion wear condition (gouging abrasion, high stress crush abrasion, low stress sliding abrasion)

2. Typically for Bucket protection, liner plate of conveyer, chute, hopper and crusher, hammer, jaw plate, liner plate etc.

Standard Packing:

1) Poly wood crates, Poly-wood pallets, with oil film inside.

2) Paper crate with oli film inside: