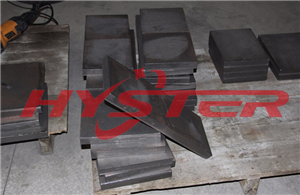

Laminated wear plates

Brand : HYSTER

Product origin : China

Delivery time : 5 days

Supply capacity : 200 tons per month

Laminated wear plates

Laminated WearPlates are unique wearresistant materials in that they combine very high wear resistant qualities ofa white iron(ASTM A532 15/3CrMo, 700BHN – 63HRc)with a weldable & high impact toughness mild steel through a metallurgicalbond to create a product that is exceptionally resistant to impact and abrasionwhile retaining.

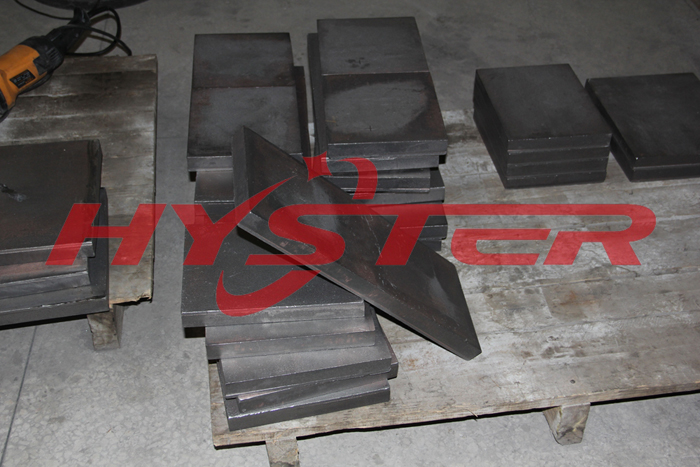

Hyster laminated wear plate products can be made to the customers' specification or supplied from our range of stock sizes. Hyster's laminated wear plate products can be custom designed to meet any situation regardless of any size and shape concerns.

Hyster can also supply cut and shaped liners to be strategically placed on fixed plant equipment so that a unique wear package can be created, maximising wear life. This makes the laminated wear plates the perfect material for chutes, drop boxes, bin and hopper liners.

Hyster primarily supplies cast billet and liner plates produced to the ASTM A532 15/3CrMo specifications. However, Hyster can produce liner plates from the following alloys on special request:

NiHard 4

Nihard 1 & 2

27 Chrome Alloy

20/1 White Iron

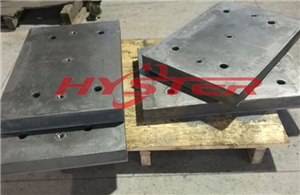

● Minimum thickness 12mm (6mm whiteiron + 6mm mild steel base)

● Maximum thickness 160mm

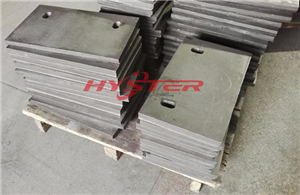

● Maximum dimension without splice L x W: 900x600mm

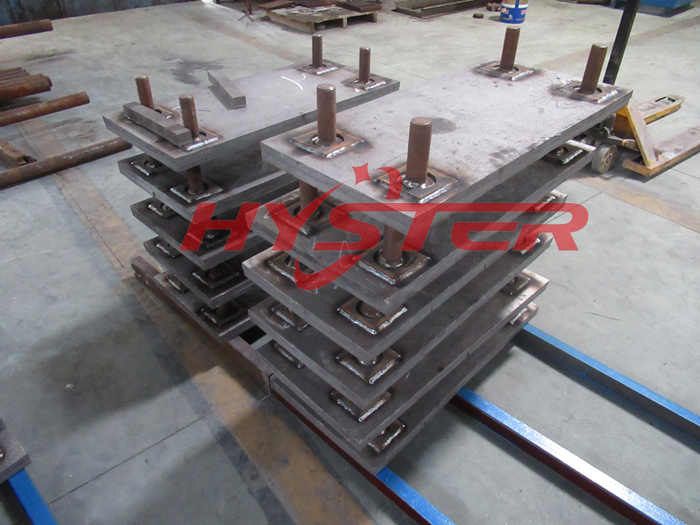

● Washers, Nuts, Studs, Threads, Holesare available.

Note: Studs Extra

If arc studs are required, pleasestipulate the size and position required.

Washers, Nuts,Studs, Threads, Holes are available.