Hyster made DOMITE (700 BHN) Chocky Bar CB25/40/50/65/80/90/100/130/150

Brand : Hyster, Domite

Product origin : China

Delivery time : 5 days

Supply capacity : 100tons per month

DOMITE (700 BHN) Chocky Bar CB25,CB40,CB50,CB65,CB90,CB100,CB130,CB150 Hardness:700BHN,63HRC Bucket/shovel wear protection

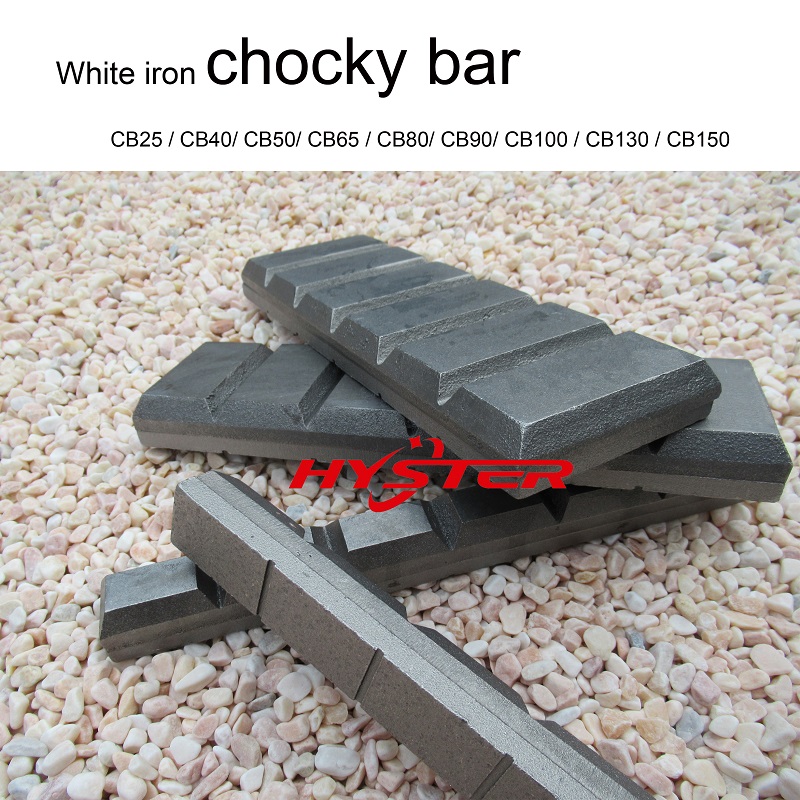

DOMITE Chocky Bars

This product has long been the most popular wear item in the DOMITE range.

The Hyster made DOMITE (700 BHN) Chocky Bar was developed many years ago as an alternative to expensive, labour intensive, hard facing welding methods.

Applications for DOMITE Chocky Bars are wide and varied, ranging from specific wear protection on buckets for loaders, excavators and draglines machines, or for weld-on hammer tips for the re-cycling industry, or chute linings and rock box edges.

Chocky bars are so easy to use! No storage problems or excessive cutting into strips required when compared to sheets of wear plates. There is also no pre-heating or post heating required when welding DOMITE bars into place.

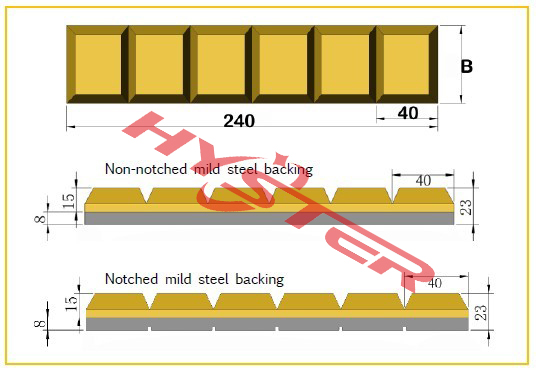

DOMITE Chocky Bars are easy to cut and form onto inside and outside contoured surfaces. Users can calculate their own lay-outs and patterns depending on the area and shape of the parts that they want to protect. The notches in the Chocky Bar casting and/or backing plate assist in cutting them to size or bending them to shape to suit the application.

Talk to us about the use of DOMITE Chocky Bars for your particular application. Chances are someone is already using it successfully for that same application somewhere around the world.

Item No. | Size (mm) | Dimension(mm) | N.W. (kg) | |||

A | B | C | D | |||

CB 25 | 240x25x23 | 240 | 25 | 15 | 23 | 0.9 |

CB 40 | 240x40x23 | 240 | 40 | 15 | 23 | 1.5 |

CB 50 | 240x50x23 | 240 | 50 | 15 | 23 | 1.9 |

CB 65 | 240x65x23 | 240 | 65 | 15 | 23 | 2.5 |

CB 80 | 240x80x23 | 240 | 80 | 15 | 23 | 3.2 |

CB 90 | 240x90x23 | 240 | 90 | 15 | 23 | 3.5 |

CB 100 | 240x100x23 | 240 | 100 | 15 | 23 | 3.9 |

CB 130 | 240x130x23 | 240 | 130 | 15 | 23 | 5.4 |

CB 150 | 240x150x23 | 240 | 150 | 15 | 23 | 6.0 |

Laminated wear blocks---the most common types are:

1) Chocky bars (CB 25. CB40, CB50, CB65, CB80, CB90, CB100, CB130. CB150)

2) Standard wear bars (DLP201A, DLP 125, DLP184, DLP528, DLP619, DLP451, DLP450, DLP2230, DLP2017, DLP4, DLP919, DLP1191, DLP515, DLP200, DLP271, DLP270, DLP508, DLP115, DLP337, DLP1101, DLP343 )

3) Shaped wear bars

4) Wear buttons& donuts(WB60, WB75, WB90, WB110, WB115, WB150, DLP1920, DLP1921, DLP1994, DLP2196)

5) Shredder/Grinder hammer tips (DLP1654,90X90X50mm; DLP653,90X90X45mm; DLP1927, 90X90X55mm)

6) Bi-metallic wear plates

7) Knife edges(DLP1065-22, 203X22X50MM; DLP1265-22,305X22X50MM; DLP1065A-16, 203x16x50mm, DLP1065A-25, 203x25x62mm; DLP1265A-25, 305x25x56mm)

8) Skid bars, skid blocks(DLP412, 250x150x45mm; DLP413, 200x150x45mm; DLP414, 250x250x45mm)

9) Wafer strips, WS25, WS40, WS50, WS65;

10) Elbow wear blocks

11) Other sizes and shapes

12) Multi-function gradient cutter tooth

13) Rockbox liners

14) Micro-ledges

Overlay wear plates: standard sheet size 1500x3000mm, thickness 4+4(8mm), 6+4(10mm), 6+6(12mm), 8+5(13mm), 8+6(14mm), 10+5(15mm), 10+10(20mm), 12+12(24mm), 12+17(29mm).

HYSTER WEAR SYSTEM

Hyster White Iron Wear Block(700BHN-63HRC)-- Range of products based on a composite white iron wear surface metallurgically bonded to a weldable mild steel backing plate. Wear block is fixed to the surface of fixed and mobile plant equipment, such as mining buckets and chutes, where protection from severe abrasion is required.

Hyster Overlay Wear Plates--Chromium carbide clad wear plate manufactured in HYSTER and marketed worldwide. Overlay plate is well suited to fixed and mobile plant equipment associated with the construction, mining and resource industries; particularly iron ore, coal, cement and steel applications.

Hyster NiHard--Abrasion and high impact resistant product. It is often cast into billets and liners and used extensively in the mining, construction and mineral processes industries, particularly in bulk handling situations.

Hyster Tungsten Carbide—High standard abrasion resistant product. It is often used where the application has no impact force or very slightly impact.

Features and Benefits

Reduced Maintenance

• Protects any high wear area, eliminating the need for frequent rebuild or replacing wear plate

• Lasts longer than other wear protection

• Excellent alternative to hard facing which can lead to cracking of major structural components Increased Productivity

• Reduced maintenance ensures maximum machine availability

• Wide variety of shapes and sizes allows small areas to be protected, minimizing the affect on penetration and material flow

Lower Operating Cost

• Can be fit to flat or curved surfaces, eliminating the need to have wear plate formed to fit

• Bucket life is significantly increased, minimizing repair and new bucket orders

Typical Data Numbers:

>white iron wear blocks life is 50% greater than that of Ni Hard Irons.

>At least 7 times longer than A.R. type steels 360/400 BHN

>5 times the wear rate of Manganese Steel

>3 times the wear rate of Tapco Weld Hardfacing

>4 times the wear rate of Astralloy-Vulcan

>16 times the wear rate of Carbon Steel

>3 times the wear rate of 500 BHN A.R. Plate

FAQ:

Q: Are you a trade company or a manufacturer?

A: We are ISO9001:2008 Certificated factory.

Q: How long is your delivery time?

A: Generally it is 5 days if the goods are in stock. or it is 15 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% in advance.,balance against copy of B/L, payable via T/T.

- Download

- Hyster Catalogue 2017(English).pdf