Composite wear liners

Brand : Hyster, Domite

Product origin : China

Delivery time : 5 days

Supply capacity : 200 tons per month

Composite wear liners

Composite Material of Chrome White Iron with Mild Steel

INTRODUCTION

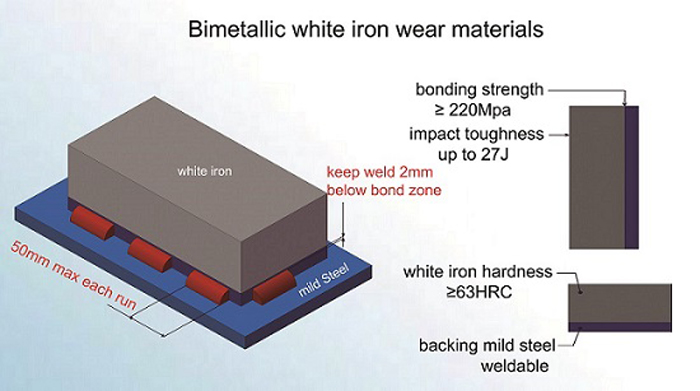

Composite wear liners are unique wearresistant materials in that they combine very high wear resistant qualities ofa white iron(ASTM A532 15/3CrMo, 700BHN – 63HRc)with a weldable & high impact toughness mild steel through a metallurgicalbond to create a product that is exceptionally resistant to impact and abrasionwhile retaining.

1. Properties

1.1 Advanced composite technology, good overall performance.

Bimetallic high-chrome white iron wear products is made of high chromium white iron casting and mild steel through vacuum brazing. High chromium white iron casting is the third generation since the general abrasion resistant white iron

casting and Ni-hard white iron casting. Its hardness could achieve to HRC63 after being quenched and tempered. In addition, the elements of Cr、Mo、Ni、Cu, etc in the alloy created a better integrated performance(hardness, hardenability, temper resistance).

The micro-structure of the high chromium white iron casting consists of 85% above Martensite + retained Austenite + Carbide. The main carbide is M 7 C 3 , of which the hardness is HV1400-1800, it is rod-shaped and isolated distribution in the substrate. The wear resistance of the monometallic high chromium white iron casting is very good, while its plasticity and toughness is insufficient under the working condition with big impact force and high stress (eg. Chisel-Cutting type abrasion, high stress grinding abrasion ), it will be easy to crack, even broken, which lead to the failure of the machine.

Moreover, cracks are more easily happed during welding due to its bad welding performance.

But, after bonding the high chromium white iron casting with mild steel, the shortages of the high chromium white iron casting will be solved, as the mild steel has excellent plasticity, toughness and welding performance. Its bonding strength is above 200Mpa, also guaranteed the close integration of the two materials, even under the working condition of strong impact force or big shear force.

1.2 Good corrosion resistance and high temperature resistance.

Large amount of Cr element improved the high-temperature oxidation resistance and the electrical potential in matrix, thus its corrosion resistance against acid and alkali media are also good. Its maximum service temperature is up to around 600℃. Therefore, it is suitable to work in the condition of high temperature and corrosion.

1.3 Easy to install and use.

The welding property of mild steel is excellent , it could be weld by ordinary structural steel electrode or welding wire. Or installed by bolts.

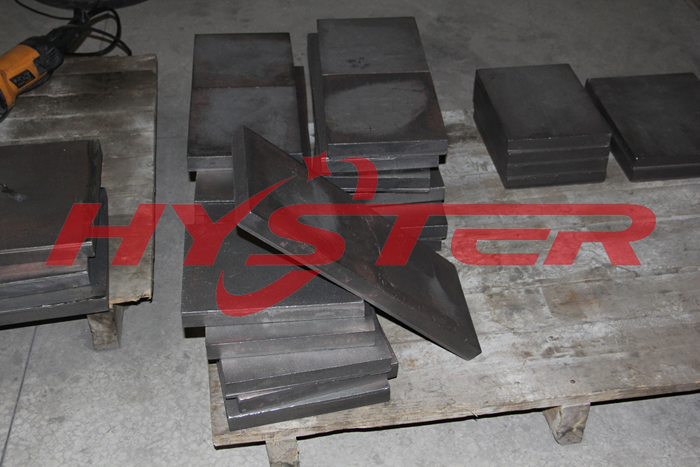

2. 1.4 Well-feasibility

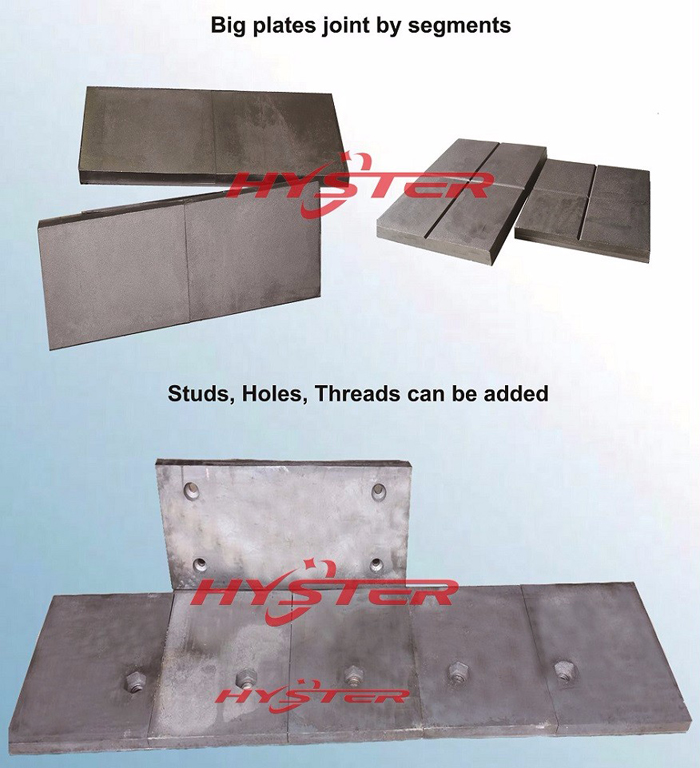

By adjusting the alloy elements of white iron and changing the heat treatment technology, different properties of composite wear material will be acquired, such as wear resistance, impact resistance, corrosion resistance, heat resistance, etc. which could almost adapt to every kind of abrasive wear. Besides, it could make into various shapes ( including tubular) and dimensions.

Note: Studs Extra

If arc studs are required, pleasestipulate the size and position required.

Washers, Nuts,Studs, Threads, Holes are available.