Chromium carbide overlay

Brand : Hyster

Product origin : China

Delivery time : 5 days

Supply capacity : 160 tons per month

HYSTER made Chromium Carbide Overlay (CCO) Wear Plate is an extra hard clad plate with additives that gives even higher abrasion resistance in high stress applications with moderate to low impact conditions

Features & Benefits

● Cost effective solution when compared to traditional abrasion-resistant steels

● Recommended for resistance to wear by abrasion, fretting, cavitation, and particle erosion in high temperature applications (up to 1100°F).

● Ideal for mild to moderate impact abrasion resistance.

● Low maintenance cost and easy installation.

● The overlay surface of CCO plate will consist of a series of beads with numerous hairline cracks in them. These properly spaced crosscheck cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

Application Specifications

● Cutting – Plasma burning, air arc, abrasive saw or water jet.

● Welding – Our CCO overlay plate can be joined by welding the substrate to substrate using 309 weld wire/rod.

● Bending – Using a press brake, forming should be perpendicular to the weld pass direction.

● Plate rolling should be performed in the directions of the overlay beads.

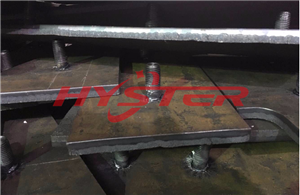

Installation: individual shaped components can be mechanically attached by welding or the use of threaded studs or countersunk bolts. In addition, self-supporting structures can be designed using hard faced sheets assembled by mechanical means or by welding.

Technical Specifications & Chemical Composition

● Hardness ranges from 58-65 HRC based on weld thickness

● Superior wear resistance

● Optimum solution for most industrial applications

| Standard Overlays | Weight | Standard Sheet Size(mm) | Overall Thickness |

| sq/m(kg) | |||

| 4 ON 4 | 62 | 1500x3000 / 1200x2400 | 8 |

| 4 ON 6 | 78 | 1500x3000 / 1200x2400 | 10 |

| 6 ON 6 | 94 | 1500x3000 / 1200x2400 | 12 |

| 5 ON 8 | 102 | 1500x3000 / 1200x2400 | 13 |

| 6 ON 8 | 109 | 1500x3000 / 1200x2400 | 14 |

| 8 ON 8 | 126 | 1500x3000 / 1200x2400 | 16 |

| 5 ON 10 | 118 | 1500x3000 / 1200x2400 | 15 |

| 6 ON 10 | 126 | 1500x3000 / 1200x2400 | 16 |

| 8 ON 10 | 141 | 1500x3000 / 1200x2400 | 18 |

| 9 ON 10 | 149 | 1500x3000 / 1200x2400 | 19 |

| 10 ON 10 | 157 | 1500x3000 / 1200x2400 | 20 |

| 12 ON 12 | 188 | 1500x3000 / 1200x2400 | 24 |

| 17 ON 12 | 222 | 1500x3000 / 1200x2400 | 29 |