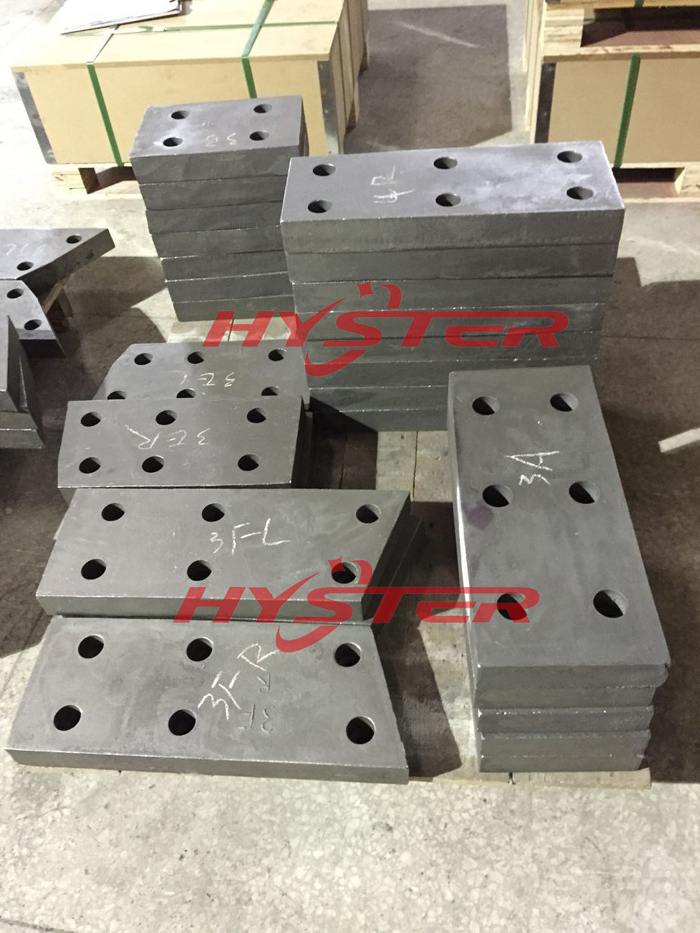

63HRC wear plates

Brand : Hyster

Product origin : China

Delivery time : 5 days

Supply capacity : 200 tons per month

63HRC wear plates

Typical application: Feeder chute and hopper wear protection

Hyster supply Chute wear liners & Hopper wear liners in material of:

--Bimetallic white iron wear liners, 63HRC/ 700HB.

--White iron wear liners, 60-63HRC

--Ni-hard 4 wear liners, wear billets, 58-63HRC

--Bimetallic white iron wear liners, 63HRC/ 700HB.

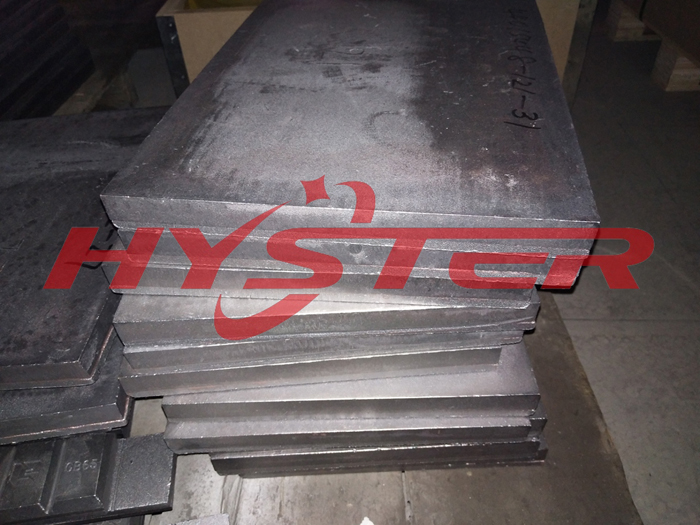

Material: ASTM A532 15/3CrMo Chrome white iron wear casting vacuum brazed onto mild steel base.

--White iron wear liners, 60-63HRC

Material:ASTM A532 15/3CrMo Chrome white iron wear casting

--Ni-hard 4 wear liners, wear billets, 58-63HRC

Material:Ni-hard 4, Ni-hard 1&2 available.

1. Sizes and Shapes can be made on request.

2. Liners can be cut to size on request.

3. Bolts/Nuts/Washers are available on request.

Features:

1. The smallest thickness for wear material we can make is 6mm.

2. Bolts/Nuts/Washers are available!

3. Holes/studs/Threads are available!

4. Wear surface is very smooth and flat, media is not easy to stick on.

5. Accoding to the feedbacks from our end users, the usage life is at least 2 times higher compared with overlay/hardfacing wear plates, at least 7 times longer than A.R type steels 360/400BHN. The thicker ones such as 20mm above wear, the usage life is much more longer. The wear resistance performance is the same from wear surface to the welding face.

6. We can make with different shapes and sizes.

7. Better cost-efficient.

8. Minimum thickness 12mm(6mm white iron + 6mm mild steel base)

Maximum thickness 160mm

Maximum dimension without splice L x W: 900x600mm