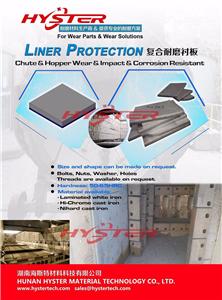

Brazed White Iron Wear Plates VS Overlay Wear Plates

Laminated White Iron Wear Plates VS Overlay Wear Plates

Bimetallic wear plates(vacuum brazed)

Material: White iron wear casting vacuum brazed onto mild steel base.

The smallest thickness for wear material we can make is 6mm.

Advantage:

1.Hardness: 63HRC/700BHN. The usage life is at least 2 times higher compared with overlay/hardfacing wear plates. The thicker ones such as above 20mm wear, the usage life is much more longer. The wear resistance performance is the same from surface to welding face.

2.Surface is very smooth and flat.

3.It can make with different shapes and sizes.

4.Better cost-efficient. Unit price is about USD5.5---USD7.5 per kilogram.

Weakness: for big sheet size, wear casting could be joint ones, not a whole sheet. For example, wear plate 1443x349x25/6mm(25mm wear, 6mm base), the wear material will be jointed with 4pcs, and mild steel base will be joint with 2pcs, joint gap is below 2mm.

Overlay/Hardfacing wear plates

Advantages:

1.Overlay thickness could range from 2mm to 20mm.

2.Sheet size could make to 1500x3000mm, also can be cut to different small sizes or shapes.

Weakness:

1.The hardfacing technology and hardfacing material that used could significantly effect the wear plate performance.

2.It has a transition layer of 1-2mm thick, this transition layer has no much wear performance.

3.The cost is much higher when hardfacing layer is thicker.

4.It can not make to different shapes, only in shape of plate or pipe.

5.Hardness is only 55-60HRC. Usage life is only 1/3 compared with white iron material.

6.The surface is very rough.

7.From surface to the joint face, its wear performance is weaker during the usage time.

8.Lower cost-efficient. Unit price is about USD2.2---USD6.0 per kilogram.

Both of them are easy for installation, studs and bolts, holes, threads could be machined for different installation purpose.

Both of them are exceptionally resistant to impact and abrasion while retaining.